Type

Twin wall & Multiwall

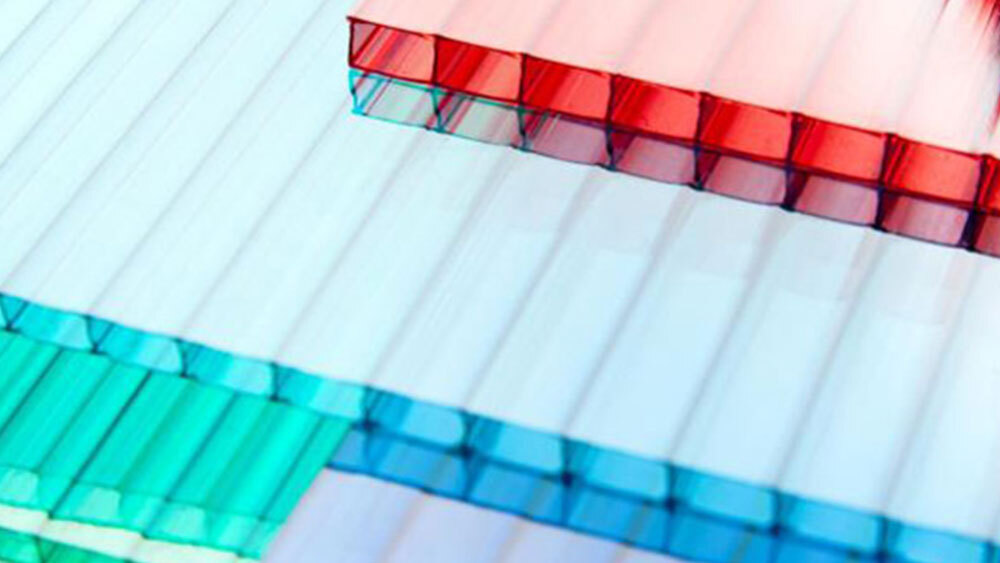

Colour

Clear, Opal, Green, Blue, Lake Blue, Smoke Grey, Bronze, Metallic Grey

Thickness Range

4MM, 6MM, 8MM & 10MM

Dimension (Width)

1.22 MTR & 2.1 MTR.

Dimension (Length)

5.8 MTR, 11.8 MTR & Customize size also

Surface Protection

Masking PE Film

AKMY Manufacturing Polycarbonate Hollow/Multiwall Sheet is own brand name of Tuff & Strong. We manufacturing with the help of Co Extrusion quoting machine quoted both side UV that makes his life and strength more others. We have been able to develop a wide range of multiwall polycarbonate sheets , each with its own specific property , to meet the demands of the various market segments.

PC is a unique engineering thermoplastic which combines a high level of mechanical, optical and thermal properties. The versatility of this material makes it suitable for many engineering applications. PC has 8 to 15 years lifespan durability that makes it suitable for everywhere usage for any interior and exterior applications. It have excellent light transmission up to 90 % as based as colour and thickness.

Tuff & Strong MW sheets insulation against heat & cold temperature between -40°C and +120°C. It Have High thermal insulation, high impact resistance, high sound insulation, fire retardant, excellence structural durability, excellence resistance to chemicals, weather resistance, UV Quoted.

Tuff & Strong MW Sheets glazing system offering design freedom in several segment of building industry like commercial, domestic & industrial applications. It has some addition benefit like – light weight , energy efficient , strong & durable & pocket friendly cost effective as per the applications.

These Sheets are mostly used for both residential and commercial flat/ curved roof glazing & cladding, wall cladding, sound barrier walls, skylights, covered walkways, greenhouse, warehouse , swimming pools, shopping malls, airports, railway station, gazebo, garden centre roofing, sun sheds for stadium & bus shelters, signage and displays & digital advertising.

Why use PC Multiwall Sheet

Light Weight

Chemical Resistance

Dimensional stability

Weather Resistance

Impact resistance

Barrier Property

Technical Properties

| Twinwall Property | 4 MM | 6 MM | 8 MM | 10 MM |

|---|---|---|---|---|

| Area weight | 0.7 kg.m2 – 0.8kg/m2 | 1kg/m2 – 1.3 kg/m2 | 1.35 kg/m2- 1.5 kg/m2 | 1.55 kg/m2 – 1.7kg/m2 |

| Sheet width | 1,220 mm – 2,100 mm | 1,220 mm – 2,100 mm | 1,220 mm – 2,100 mm | 1,220 mm – 2,100 mm |

| Possible delivery lengths | 2,000 to 12000 mm (Standrad – 11800 mm) | 2,000 to 12000 mm (Standrad – 11800 mm) | 2,000 to 12000 mm (Standrad – 11800 mm) | 2,000 to 12000 mm (Standrad – 11800 mm) |

| Minimum permissible cold-bending radius | (1) 680 mm | (1) 900 mm | (1) 1200 mm | (1) 1500 mm |

| Light transmittance τD65 clear 1099 | ca. 79 % | ca. 79 % | ca. 81 % | ca. 80% |

| UV-absorbing Property | Yes | Yes | Yes | Yes |

| White 1125 | ca. 25 % | ca. 21 % | ca. 21 % | ca. 20 % |

| White 1146 | ca. 76 % | ca. 77 % | ca. 77 % | ca. 69 % |

| Bronze 1845 | ca. 43 % | ca. 48 % | ca. 77 % | ca. 40 % |

| Green 1650 | ca. 51 % | ca. 55 % | ca. 57 % | ca. 53 % |

| Blue 1545 | ca. 40 % | ca. 42 % | ca. 43 % | ca. 41 % |

| Heat transfer coefficient | (ASTM C 976/90) Ug 4.1 W/m2 K | (ASTM C 976/90) Ug 3.7 W/m2 K | (ASTM C 976/90) Ug 3.3 W/m2 K | (ASTM C 976/90) Ug 3.1 W/m2 K |

| Coefficient of thermal expansion | α 0.065 mm/m °C | α 0.065 mm/m °C | α 0.065 mm/m °C | α 0.065 mm/m °C |

| Possible expansion due to heat and moisture | 3 mm/m | 3 mm/m | 3 mm/m | 3 mm/m |

| Max. service temperature without load | 120 °C | 120 °C | 120 °C | 120 °C |

Applications & Uses

Signage Industry

Advertising Industry

Interior Decoration

Office Partition

Glazing

Ceiling Lighting

Door/Window Panels

Display

Showcases and photo frames

Advertising Light Box

Sliding & Bathroom Doors